-

Läs mer

Läs mer

Läs merBorrkronor för spränghålsborrning

-

Läs mer

Läs mer

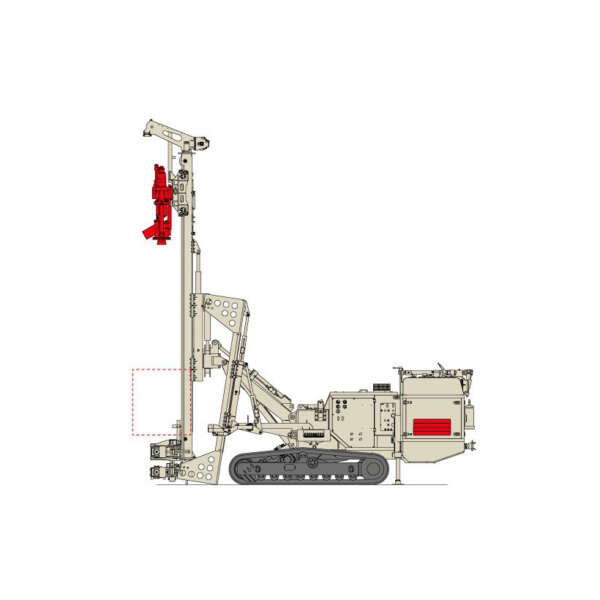

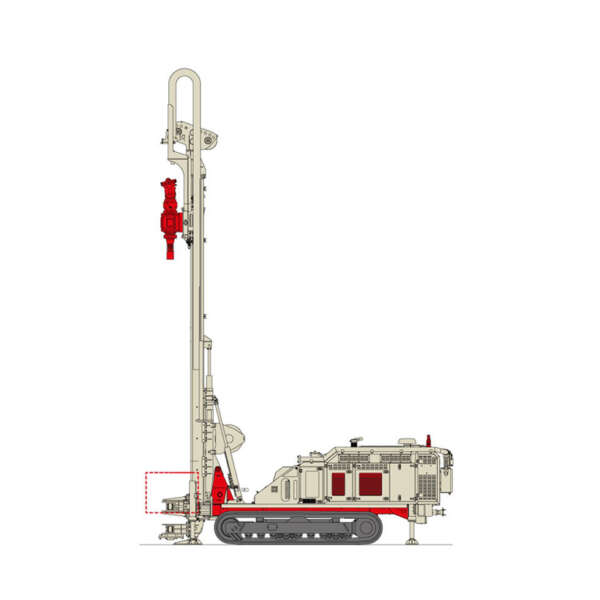

Läs merCH 450 pålningsmaskin

-

Läs mer

Läs mer

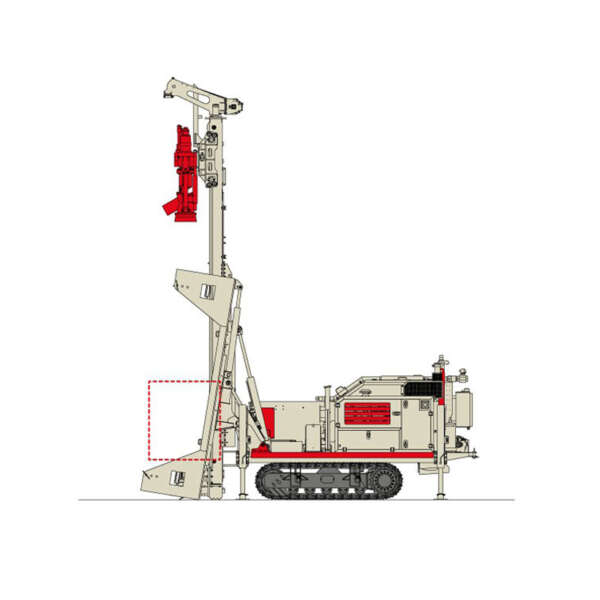

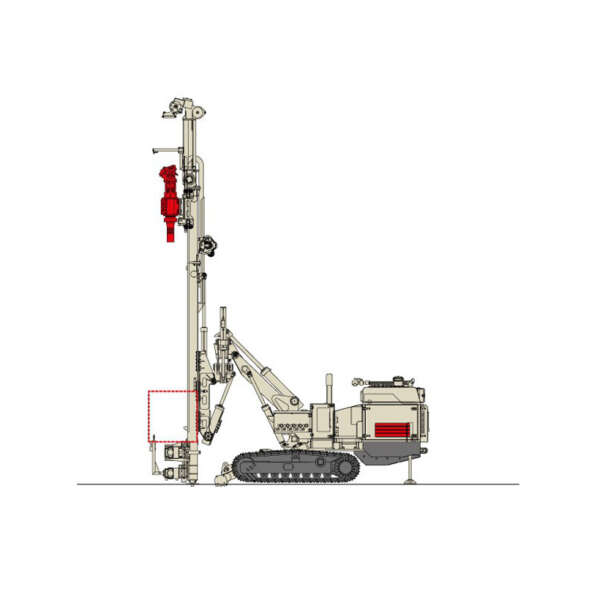

Läs merCH 650 pålningsmaskin

-

Läs mer

Läs mer

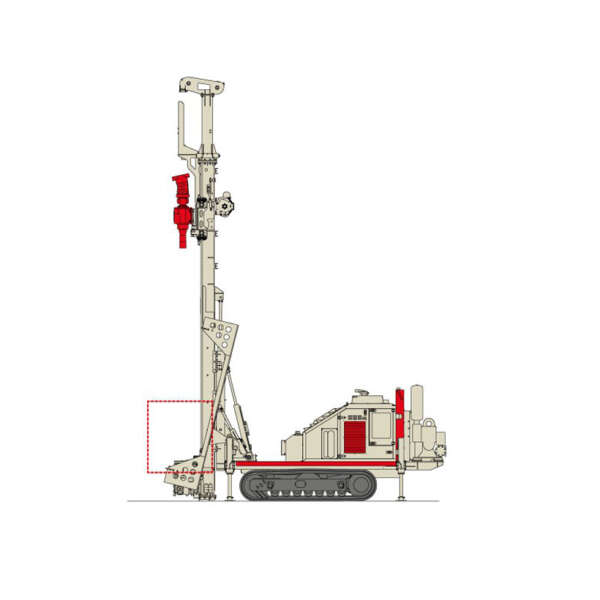

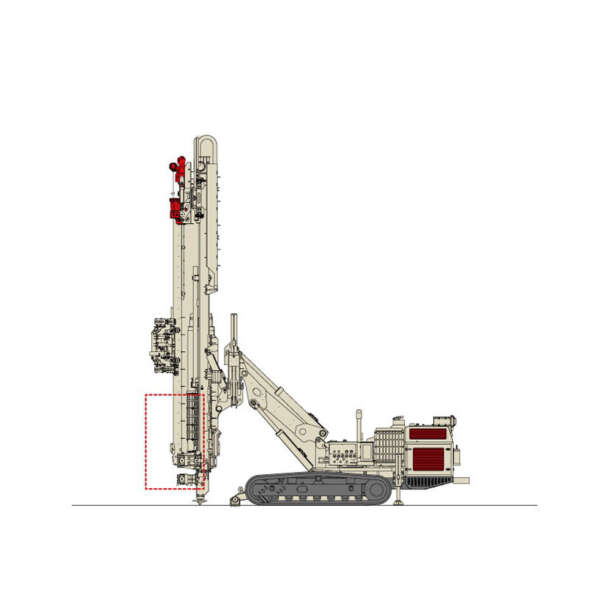

Läs merCPH rörhanteringssystem

-

Läs mer

Läs mer

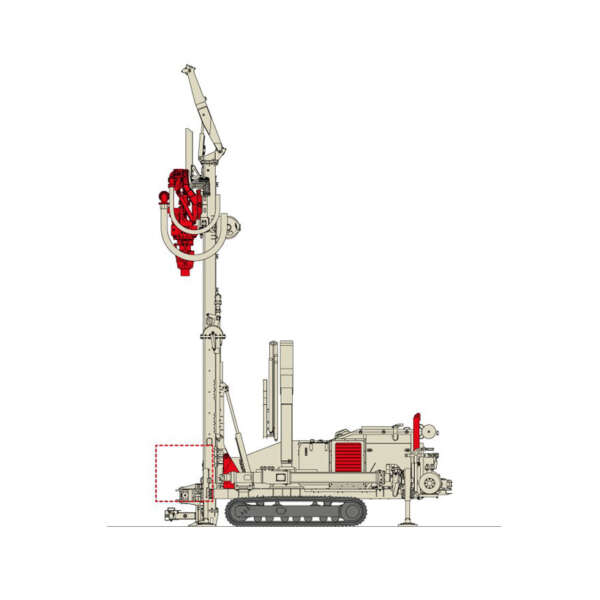

Läs merCX RC-borr

-

Läs mer

Läs mer

Läs merCXT RC-borr

-

Läs mer

Läs mer

Läs merDTH-Bit – Brunns- och energiborrning

-

Läs mer

Läs mer

Läs merDTH-Bit – Grundläggning

-

Läs mer

Läs mer

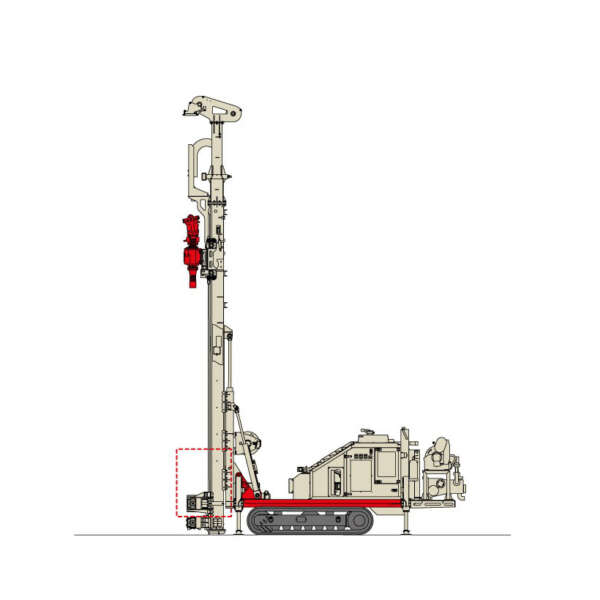

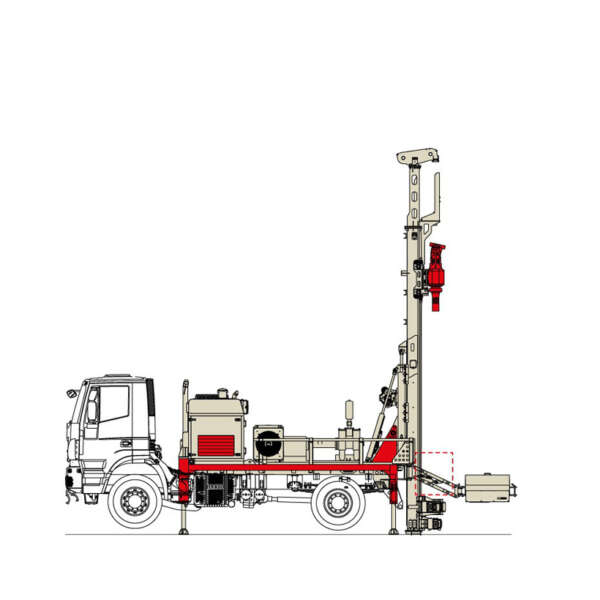

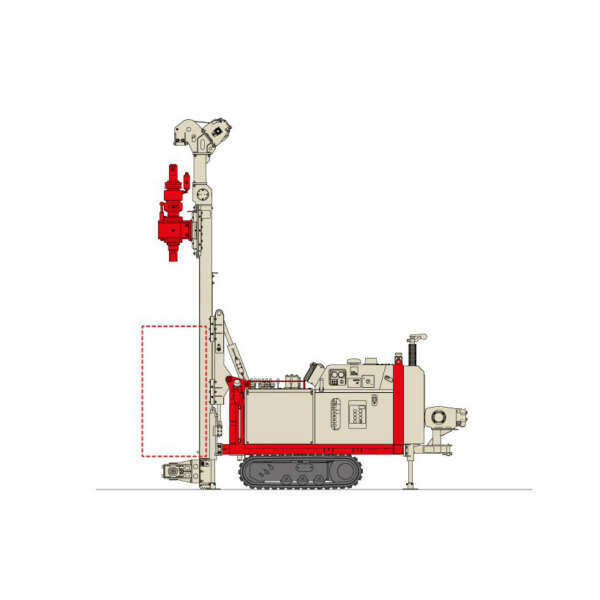

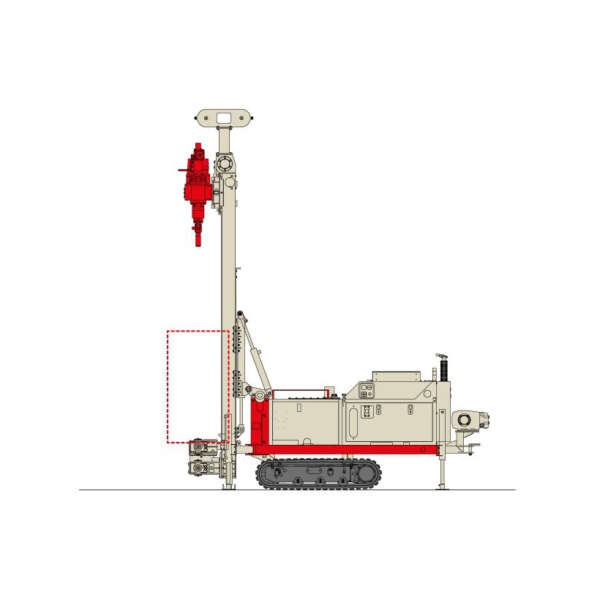

Läs merGEO 105

-

Läs mer

Läs mer

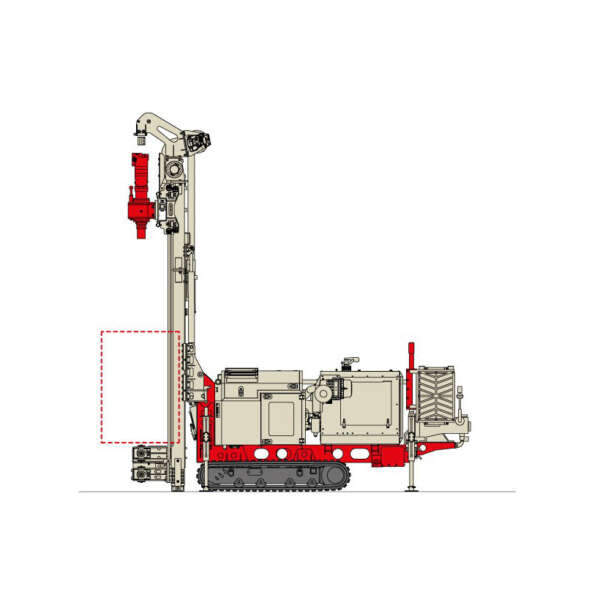

Läs merGEO 205

-

Läs mer

Läs mer

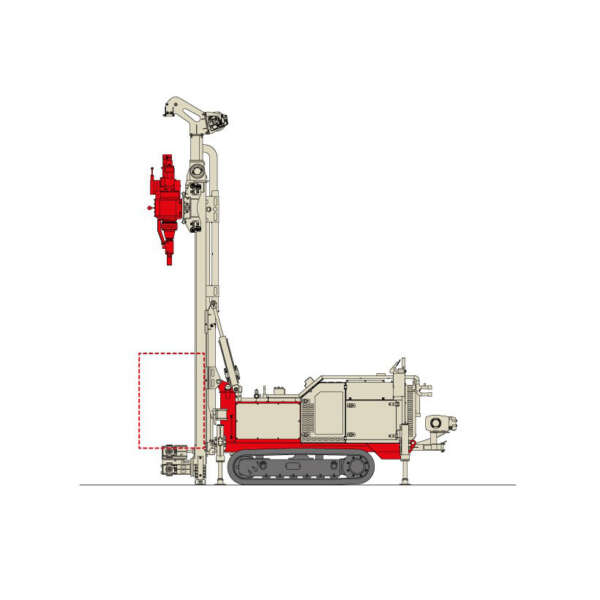

Läs merGEO 300

-

Läs mer

Läs mer

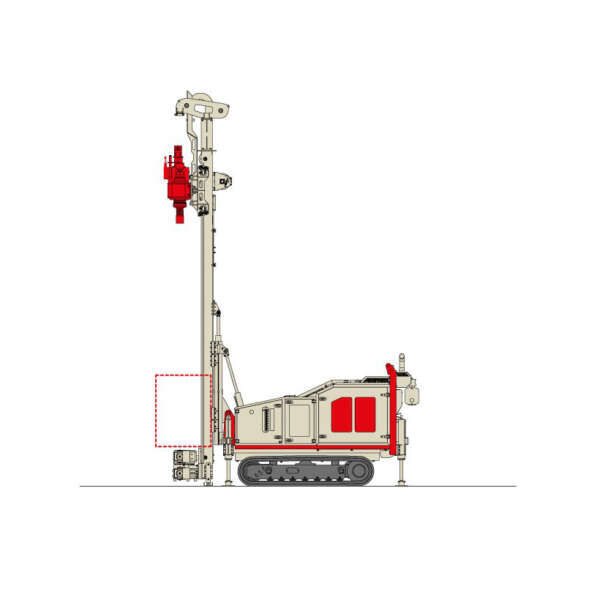

Läs merGEO 305

-

Läs mer

Läs mer

Läs merGEO 405

-

Läs mer

Läs mer

Läs merGEO 500-501

-

Läs mer

Läs mer

Läs merGEO 600

-

Läs mer

Läs mer

Läs merGEO 601

-

Läs mer

Läs mer

Läs merGEO 602-602 GT

-

Läs mer

Läs mer

Läs merGEO 655

-

Läs mer

Läs mer

Läs merGEO 700 GT

-

Läs mer

Läs mer

Läs merGEO 900-900 GT

-

Läs mer

Läs mer

Läs merGEO 901-901 GT

-

Läs mer

Läs mer

Läs merHyper 101

-

Läs mer

Läs mer

Läs merHyper 121

-

Läs mer

Läs mer

Läs merHyper 31

-

Läs mer

Läs mer

Läs merHyper 41

-

Läs mer

Läs mer

Läs merHyper 51

-

Läs mer

Läs mer

Läs merHyper 63

-

Läs mer

Läs mer

Läs merHyper 81

-

Läs mer

Läs mer

Läs merMC 12

-

Läs mer

Läs mer

Läs merMC 15

-

Läs mer

Läs mer

Läs merMC 22

-

Läs mer

Läs mer

Läs merMC 28

-

Läs mer

Läs mer

Läs merMC 40

-

Läs mer

Läs mer

Läs merOSM katalog

-

Läs mer

Läs mer

Läs merRobit DTH Prime

-

Läs mer

Läs mer

Läs merRobit DTH SF

-

Läs mer

Läs mer

Läs merRobit DTH SR

-

Läs mer

Läs mer

Läs merRobit® DTH Nova – Ringborrssystem

-

Läs mer

Läs mer

Läs merRobit® DTH-REC

-

Läs mer

Läs mer

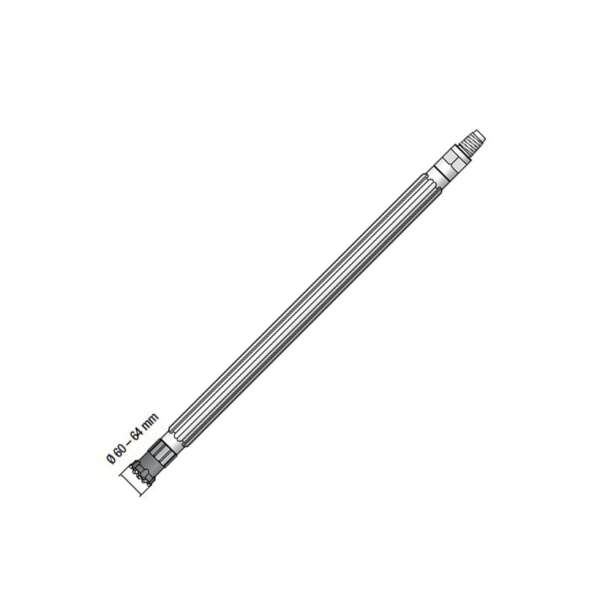

Läs merStänger för spränghålsborrning

-

Läs mer

Läs mer

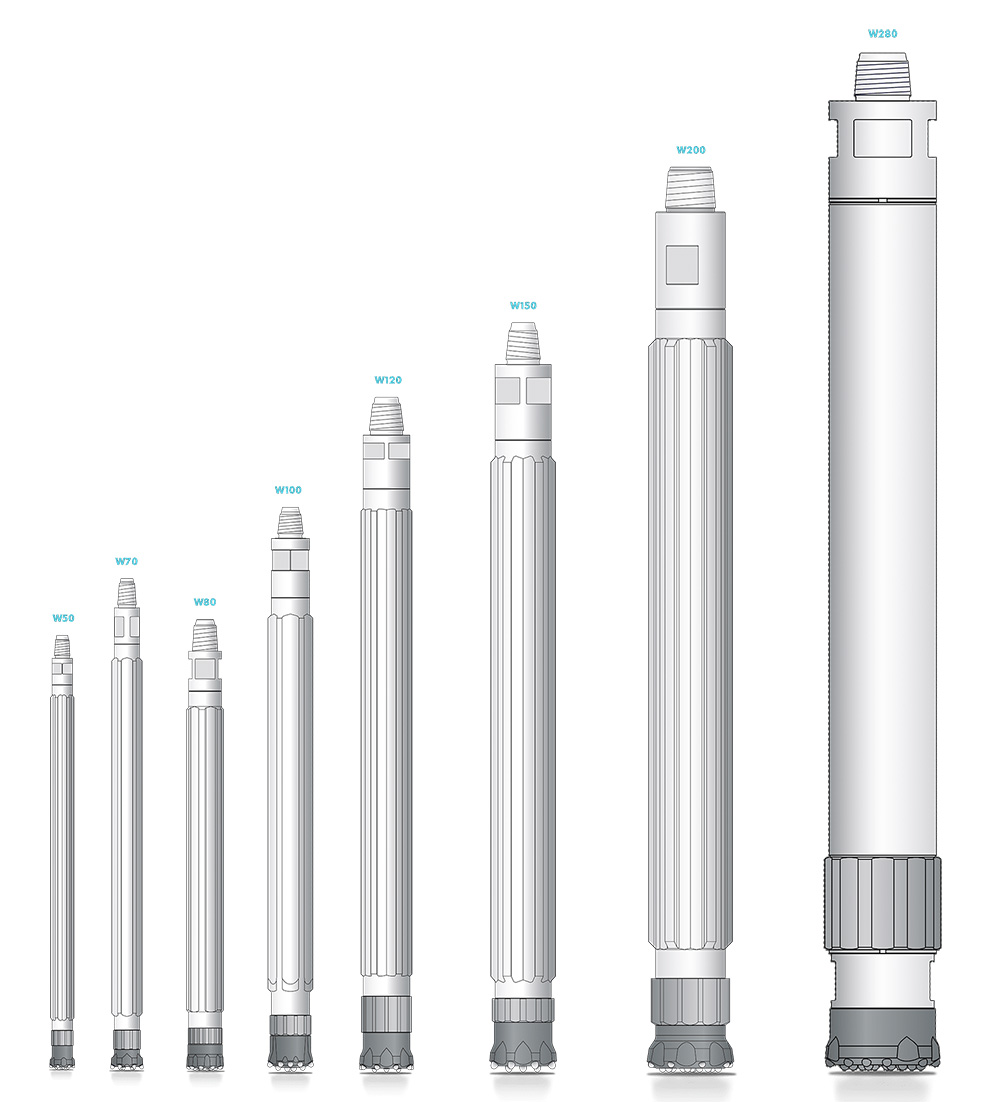

Läs merW 100 hammare

-

Läs mer

Läs mer

Läs merW 100 JG hammare

-

Läs mer

Läs mer

Läs merW 120 hammare

-

Läs mer

Läs mer

Läs merW 150 hammare

-

Läs mer

Läs mer

Läs merW 200 hammer

-

Läs mer

Läs mer

Läs merW 50 hammare

-

Läs mer

Läs mer

Läs merW 70 Hammer

-

Läs mer

Läs mer

Läs merW 80 hammare

-

Läs mer

Läs mer

Läs merWH4 HP

-

Läs mer

Läs mer

Läs merWH5

-

Läs mer

Läs mer

Läs merWH5 TL

-

Läs mer

Läs mer

Läs merWH6

-

Läs mer

Läs mer

Läs merWH6 TL